In the business sphere, production plays one of the key roles in terms of creating and delivering goods and services. It contains resources, activities, and processes involved in transforming inputs into valuable outputs. Production is the most fundamental component of any organization. It drives efficiency, profitability, and customer satisfaction. We will be exploring the concept of production in business, its meaning, and some key factors that contribute to its success.

What is production and what are its components?

By definition, product creation is the systematic transformation of inputs into outputs that carry some value for customers. It consists of a series of activities, including sourcing raw materials, utilizing technology and labor, and managing processes to create finished goods or deliver services. The components of the process include both tangible and intangible elements. For example, equipment, machinery, human resources, information systems, and organizational structures.

Productivity and Efficiency

Successful production in business must have productivity and efficiency at its core. The latter refers to achieving maximum output with minimum possible inputs, optimization of resources, and minimizing waste. More concretely, this involves eliminating bottlenecks, adopting lean principles, and presenting streamlining processes. On the other hand, productivity focuses on the ratio of output to input. It measures the efficacy of product creation activities. By improving these two factors, businesses can increase output, reduce cost and enhance their overall competitive advantage.

Assurance and Quality Control

Quality control insinuates monitoring and inspecting products or services throughout the product creation process to ensure they meet predetermined standards. The latter and its high-quality maintenance are crucial. Quality assurance, however, involves implementing processes and systems that prevent defects and help maintain consistent quality. By prioritizing both of these components, businesses are able to build customer trust, strengthen brand reputation and minimize returns or customer dissatisfaction.

Optimization and Capacity Planning

Production management cannot run effectively without capacity planning and optimization. The organization’s ability should be assessed to ensure meeting current and future demands and enabling the alignment of resources with the company’s goals. Capacity planning assists businesses with efficient resource allocation and avoidance of bottlenecks or idle capacity. In addition, capacity planning is required to utilize the machinery, labor, and facilities.

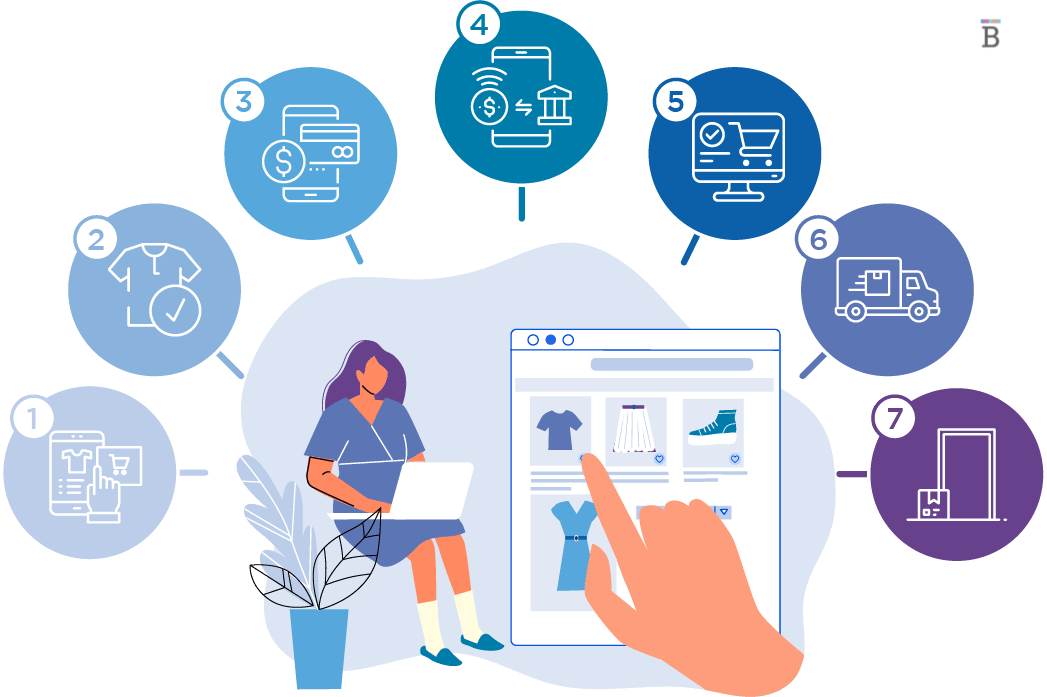

Management of the Supply Chain

Production is very closely intertwined with supply chain management. For seamless processes, it is essential to have efficient coordination of suppliers, inventory management, distribution channels, and transportation. When the supply chain is effectively minimized, businesses can decrease lead times while also reducing costs and ensuring a steady flow of materials as well as inputs for product creation.

Continuous improvement and Innovation

In order to stay competitive, businesses should prioritize continuous improvement and innovation. Done by embracing new technologies, process enhancements and keeping up with new trends that emerge on the relevant platforms. Product innovation can drive efficiency, reduce costs and meet evolving customer needs. Aside from this, adopting a culture of constant improvement can encourage employees to identify inefficiencies, propose solutions and contribute to the overall process of product creating operations.

Environmental Sustainability

In the current business landscape, environmental sustainability has become an integral part of effective product creating strategies. Eco-friendly practices, such as waste reduction and responsible sourcing should be a part of the process. This is in order to ensure environmental safety, brand reputation enhancement, and attraction of environmentally-conscious customers. This will widen the scope of business inclusivity and attract even more potential streams for profit and credibility.

What to Consider

As the readers could see, production in business is of critical importance. It encompasses activities, resources, and processes required to transform inputs into beneficial outputs. Business owners should consider a lot of factors to make sure that the quality meets current and future standards.

These factors include, but are not limited to: supply chain management, innovation, sustainability, capacity planning, quality control, productivity, efficiency, and environmental cautions. By doing so, businesses will optimize their production operations and gain a competitive edge.

Successful product not only drives profitability, organizational growth, and customer satisfaction but also makes a pillar for holistic business success. Continuous evaluation and improvement of these processes will help organizations adapt to changing market demands and stay in touch with the current dynamics of the business environment.

Leave a Reply

View Comments